Press Release

Wuppertal August 21, 2025

Riedel Artist Powers Steel Mill Comms Upgrade at BlueScope’s Port Kembla Steelworks

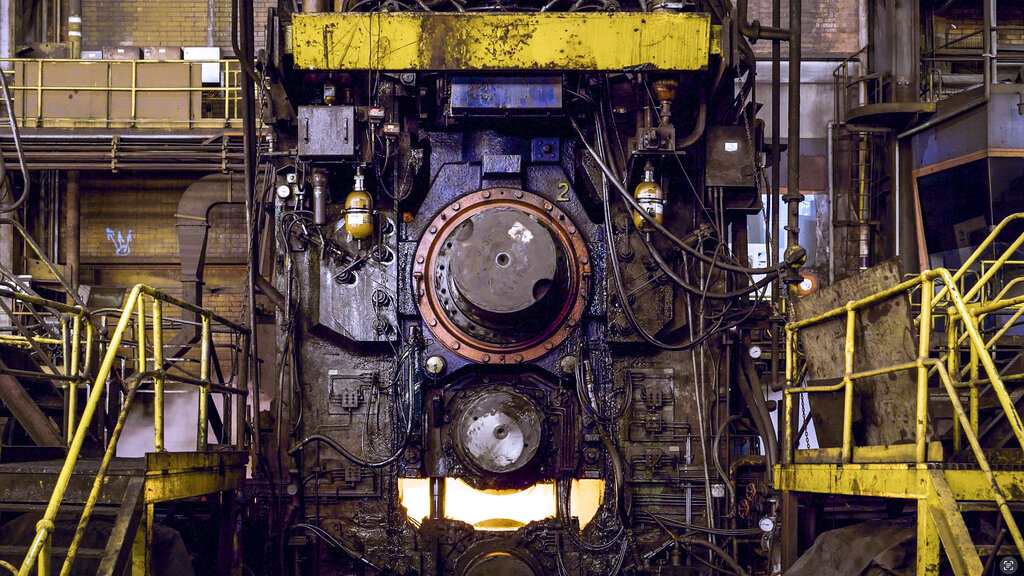

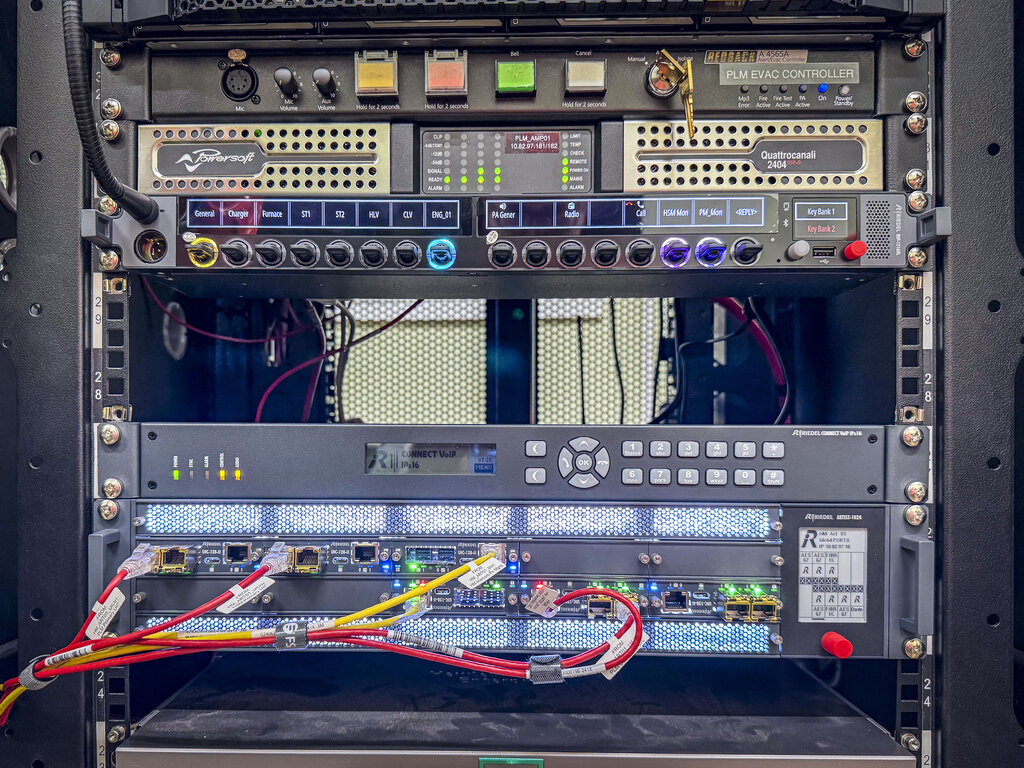

Producing over three million tonnes of steel annually, the Port Kembla Steelworks is a large-scale and complex industrial operating environment. As the steelworks fast approaches its 100-year anniversary in 2028, these assets require ongoing upkeep and capital re-investment to maintain operational security whilst safely managing the inherent hazards of an operating steelworks. The Hot Strip Mill was built in the 1960s, with an ageing two-wire analogue partyline system that could no longer meet the demands of modern operations. Recognizing that effective communication is vital for both safety and efficiency, BlueScope initiated an extensive review to identify a more capable solution. Following a thorough evaluation, the company selected Riedel’s Artist ecosystem, renowned for its scalability, audio clarity, and built-in redundancy.

“We started exploring options from different vendors and aligning them with our requirements. Key needs included: partyline communication, flexibility in call routing, and the ability to broadcast to all, or communicate with, individual control booths (‘pulpits’),” said Benjamin Yeatman, Hot Mills Electrical Engineering Team Leader at BlueScope. “With Riedel, we can tailor communication between pulpits, implement partylines, and integrate external hardware. The integration was seamless and enhanced communication across the plant.”

One of the most significant improvements brought by the new system is its integration with BlueScope’s Tetra digital radio network via Riedel’s Juggler Tetra interface. Previously, communication between elevated control booths and the crew on the factory floor was fragmented. The Riedel deployment has unified these channels into a single, intelligent communication framework.

The Artist system also interfaces with a range of third-party audio and logic devices. By integrating distributed speaker and microphone systems and GPIO-triggered functions, BlueScope has created a dynamic and responsive comms environment tailored to its high-stakes operations. The intercom also plays a pivotal role in emergency management, with the ability to override regular communication to ensure safety-critical announcements reach all operators instantly.

“Support was also a core selection criterion,” Yeatman added. “Riedel offers robust service level agreements and local support, which is critical for our 24/7 manufacturing environment. Reliability is also essential – without comms, the process stops. Riedel’s built in redundancy in its Artist frames has proven to deliver excellent uptime and dependability.”

Beyond the technical upgrades, the Riedel system has positively influenced day-to-day operations. Communication between pulpits is now more direct and the improved audio clarity has proven particularly valuable in a noisier background environment. The accessibility of communication has also helped foster stronger collaboration across teams.

“The audio quality is excellent – loud and robust – which is especially important in our heavy industrial environment with higher noise levels,” said Karl Pajkovic, Operations Manager at BlueScope. “But more than that, the comms is bringing the team together. Being alone in a pulpit can be pretty isolating, especially for new team members, but the Riedel comms allows us to include those operators and for experienced crew to connect even better. It’s good for morale.”

Chris Johnson, Director Oceania at Riedel Communications, said: “BlueScope’s deployment at Port Kembla is a powerful example of how our Artist intercom technology – originally developed for broadcast and live production – can deliver mission-critical performance in heavy industrial environments. The integration with BlueScope’s complex operational infrastructure underlines the system’s adaptability, reliability, and effectiveness in even the most demanding conditions.”